DOI: 10.1016/j.carbon.2019.02.041

ABSTRACT

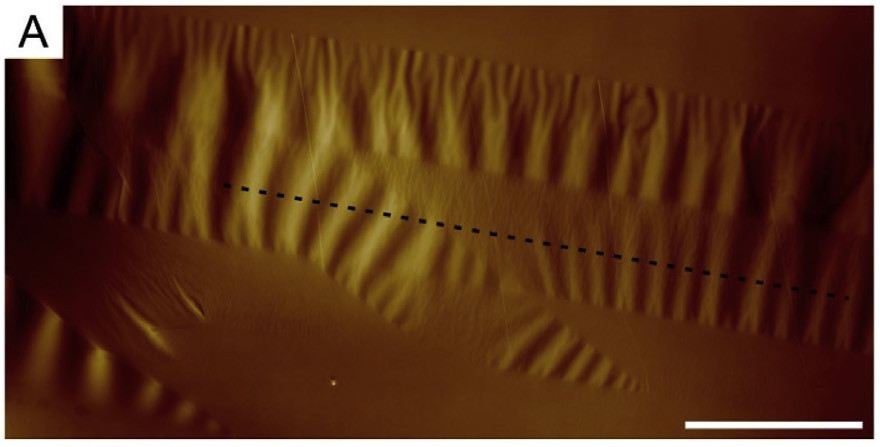

In this work we present a fabrication process for sculpturing wrinkled structures into soft polymers by thermal treatment of graphene flakes. This is accomplished by the imposition of a biaxial compressive stress field to the graphene flakes by controlled heating of graphene/polymer composites. The wrinkling patterns (amplitude, wavelength) are linearly related to the thickness of the graphene as in the case of a stiff film deposited on a compliant substrate. The orientation of the wrinkles is controlled by the geometry of the flakes, such as that long and narrow flakes exhibit perfectly parallel wrinkles perpendicular to the longer edge, while more equilateral specimens are wrinkled without any preferred orientation in the flake interior. Kelvin probe measurements showed that this type of wrinkling does not affect the surface potential of the graphene flakes. The universality of the technique is validated by sculpturing two different polymers, using mechanically exfoliated flakes as well as large graphene prepared by chemical vapor deposition. We thus demonstrate that the present approach is an excellent method for patterning the surface of soft matter in a number of applications with nanoscale features of lateral dimensions as low as ~50 nm.